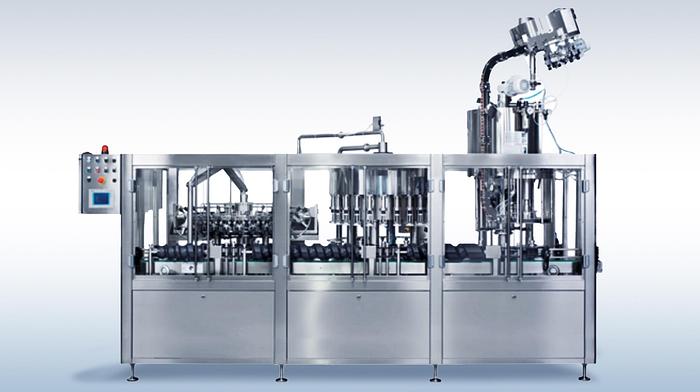

Filling, capping and labelling monoblock for juices - MFCE16

Filling, capping and labelling monoblock for juices - MFCE16

Custom Solution

Location:Milan, Italy

Description

Automatic monoblock for 250 and 750 cc PET hexagonal bottles.

System consisting of a gravitational filler with 16 spouts and a capper for plastic screw caps.

The bottles are placed in the rotating loading chamber, conveyed with a conveyor belt towards the monobloc, here the selection and transfer of the bottles takes place by an auger. In the first station there are blowers with 16 pliers, each bottle is treated individually with sterile air. Subsequently they pass to the filling station, here the bottles are raised, with plates equipped with a centering system, and the nozzle enters the container. The dosing taps are in stainless steel with heat-sanitizable gaskets. Once filled, the bottles arrive in the automatic three-head capper for screw caps. The cap is loaded automatically. The plant is completed by a 6-head labelling monoblock with container selection auger, inlet star and exit star, set of brushes for perfect label application. Production: about 5000 pcs/h. for 250 cc bottles.

Specifications

| Ideal solution for | juices - still drinks - liquids - semi-thick. |